OPI Scheme @ H&T Industrial

Without continual growth and progress, words such as improvement, achievement, and success have no meaning and “continuous improvement is better than delayed perfection”.

H&T Industrial stand by this philosophy and our goal is to improve operational effectiveness by eliminating waste, being right first time and reducing costs. To achieve these goals we introduced H&T Excellence in 2013 and later implemented an Observation, Problem & Improvement (OPI) scheme at our Blackburn site where all employees are eligible and invited to make suggestions to help reduce waste and create cost savings for the site.

The nature of H&T Excellence focusses on reducing one of 10 potential areas of waste. Continuous improvement (kaizen) events are held on a regular basis to focus on improving a specific area of the business, with a minimum of 24 workshops held at our Blackburn site per year. They are designed to provide a consistent approach to implement operational excellence throughout the Heitkamp & Thumann Group and all employees undergo an initial training session, which provides them with the essential tools to recognise potential waste in their work.

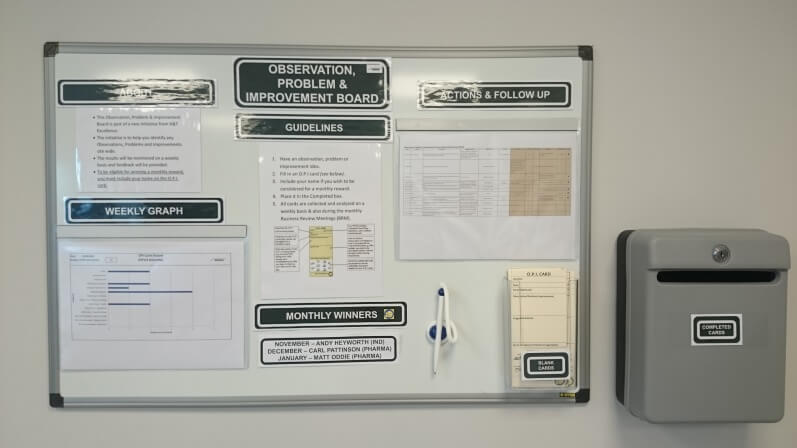

The introduction of the OPI scheme is a H&T Excellence initiative designed so employees can record their suggestions on a specially designed card and submit in a box which they can either do anonymously or including their name. The cards are then collected weekly and discussed at our business review meetings every month. The system so far has had over 230 OPI cards raised and as a site incentive there is a reward system in place for the best suggestions voted for by the management teams. Successful submissions and winners of the scheme receive a £50 voucher and their idea will be implemented across the site in the future. But all is not lost – no waste here! All suggestions submitted within the scheme are logged and even if they don’t win overall, all suitable suggestions are still implemented and actioned across the site to try and make HTI as successful and efficient as possible.

Including our employees’ thoughts and ideas not only gives us the advantage of first-hand experience and observations on potential problems but it also shows the importance of the principle “employee empowerment and development” within the continuous improvement process. As a precision engineering company we believe that being in the manufacturing industry and employing the use of heavy machinery there is always going to be opportunities for improvement. Giving our employees the chance to be heard gives us that competitive edge as we like to make our employees feel like they are making a difference whilst receiving invaluable perspective on how we run the site.

We are very proud of our OPI scheme and hope we can continue to create these improvements for our customers and ultimately become the best site we can be.

Thank you to all our employees that have contributed so far!